The Pivotal Edge pneumatically run auto hatch for dry bulk tankers operates automatically from a control at ground level improving driver and operator safety. Assisting companies meet WHS regulations requirements by offering a reliable, practical and cost effective engineering solution which virtually eliminates the working at height risks and manual task risk associated with loading dry bulk product.

Both businesses and WHS regulations aim to reduce risks and harm to employees, there are however often hazardous routine tasks that need to be performed across the country multiple times per day which need to be reassessed, evaluated and controlled on an ongoing basis. One such tasks is the opening and closing of loading hatches on dry bulk tankers. It is still common practice for drivers or operators to access loading hatches and equipment via a ladder on the back of the trailer then to manually open and close single or multiple loading hatches. Safety rails, arrest systems and in some cases loading platforms have become an industry norm to reduce fall risks there are still however significant injury risks associated with climbing up and down ladders or stairs, working on top of tankers or platforms and in performing the manual task of opening and closing hatches which are not addressed by the current safety systems.

Has your business evaluated the risks associated with loading dry bulk product and are you satisfied that appropriate controls have been put in place to reduce or eliminate the working at height and manual task risks associated with performing this task. Are you satisfied that your businesses risk review and controls around this task are current and that alternatives have been sought to eliminate these injury risks.

The new WHS regulations and codes of practice outline the duty holders responsibilities and duties of care.

New Work Health and Safety laws

Over the past two years the new harmonised Work Health Safety Acts and Regulations have been adopted by the Commonwealth, Qld, NSW, ACT, NT, TAS and SA. The WHS Regulations speak to the responsibilities of persons conducting a business or undertaking at a workplace have related to managing Hazardous Work in Chapter 4 and specifically refers in Part 4.2 to managing risks to health and safety relating to a musculoskeletal disorder associated with a hazardous manual task and in Part 4.4 managing risks to health and safety associated with a fall by a person from one level to another that is reasonably likely to cause injury. See Work Health Safety Act 2011 Regulations

Regulation 34–38 outlines “What is required to manage the risk of falls?

Referenced from SWA Managing Risk of Falls at Workplaces Code of Practice

In order to manage risk under the WHS Regulations, a duty holder must:

- identify reasonably foreseeable hazards that could give rise to the risk ?

- eliminate the risk so far as is reasonably practicable

- if it is not reasonably practicable to eliminate the risk – minimise the risk so far as is reasonably practicable by implementing control measures in accordance with the hierarchy of control

- maintain the implemented control measure so that it remains effective ?

- review, and if necessary revise, risk control measures so as to maintain, so far as is reasonably practicable, a work environment that is without risks to health and safety”

HOW TO CONTROL RISKS

The most important step in managing risks, according to Safe Work Australia involves “eliminating them so far as is reasonably practicable, or if that is not possible, minimising the risks so far as is reasonably practicable”.

In the Safe Work Australia How to Manage Work Health and Safety risks document they explain how consideration should be given to various control options and that businesses need to choose the “control that most effectively eliminates the hazard or minimises the risk in the circumstances. This may involve a single control measure or a combination of different controls that together provide the highest level of protection that is reasonably practicable.”

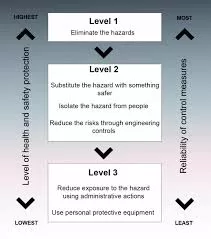

The Safe Work Australia hierarchy of risk control details that “The ways of controlling risks are ranked from the highest level of protection and reliability to the lowest as shown in Figure 2. This ranking is known as the hierarchy of risk control. The WHS Regulations require duty holders to work through this hierarchy when managing risk under the WHS Regulations.” SWA Manage Work Health Safety Risks

“Eliminating the need to work at height is the most effective way of protecting workers from the risk of falls” SWA Managing Risk of Falls at Workplaces Code of Practice

“The most effective control measure involves eliminating the hazardous manual task and its associated risk” SWA Hazardous Manual Tasks Code of Practice

- Eliminates the Manual tasks of opening and closing hatches, there is no requirement for the driver to bend down, unfasten and lift hatches.

- Eliminates the working at height risks, there is almost no need for drivers to climb onto a tanker.

- Eliminates trip, slip and fall risks, there is almost no need to climb up and down ladders and stairs and walk on top of tankers during loading